Rust Detection with Hyperspectral Imaging

on Wed Nov 09 2022

Francis Doumet

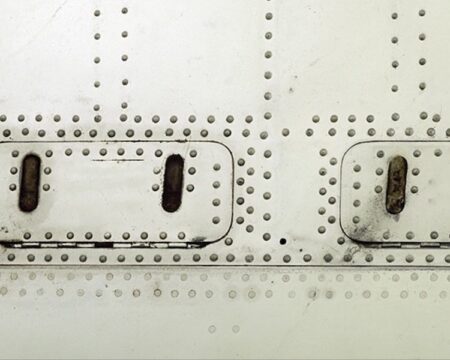

Rust is a major problem for naval vessels because it causes structural damage and can lead to leaks. Because of this, detecting rust early is crucial for naval maintenance. However, traditional methods of rust detection, such as close visual inspection, are time-consuming and often ineffective.

Hyperspectral imaging is a promising new technology that can be used for early detection of rust on naval vessels. Hyperspectral imaging works by collecting light from across the electromagnetic spectrum and using algorithms to analyze the data. This analysis can reveal the presence of rust, even when it is not visible to the naked eye.

In addition to being highly effective, hyperspectral imaging is also non-destructive and does not require physical contact with the surface being inspected. This makes it an ideal tool for detecting rust on naval vessels.

How Hyperspectral Imaging Works

Hyperspectral imaging works by using a special camera to capture images of an object at different wavelengths of light. These images are then analyzed using AI algorithms that are specifically designed to identify the presence of rust.

This technology is already being used by the military for a variety of applications, including detecting improvised explosive devices and land mines. It has also been used for medical diagnosis and agricultural monitoring.

The benefits of using hyperspectral imaging to detect rust are numerous. Perhaps the most important benefit is that it can detect very small changes in reflectance. This means that it can be used to identify problems before they become serious, such as detecting even minor changes in the chemical composition of a surface which can be an early indicator of rust formation. This saves time and money by avoiding the need for extensive repairs down the road.

In addition, hyperspectral imaging can be used to inspect hard-to-reach areas. This is especially important in the case of naval vessels, which often have large surfaces that are difficult to inspect visually. The use of hyperspectral imaging can help ensure that no area goes unchecked and that rust is detected as early as possible.

Finally, another advantage of hyperspectral imaging is that it can be used to detect rust beneath paint or other coatings. This is because light reflects differently off of bare metal than it does off of paint or another coating. By analyzing the reflectance data, hyperspectral imaging can accurately detect rust even when it is hidden from view.

Conclusion

Hyperspectral imaging is a powerful tool for early detection of rust on naval vessels. It is non-destructive and does not require physical contact with the surface being inspected, making it ideal for regular monitoring of large surfaces. In addition, hyperspectral imaging can detect very small changes early, saving precious resources if material degradation is detected early. Because of these advantages, hyperspectral imaging is a prime candidate for use in naval maintenance programs.