How Hyperspectral Imaging is Revolutionizing Industrial Recycling

on Wed Jan 04 2023

Francis Doumet

In a world where sustainability is becoming increasingly important, industrial recycling facilities are a powerful way to reduce waste and turn it into something useful. But how can we ensure that the materials being recycled are sorted accurately and efficiently? Hyperspectral imaging offers a powerful solution in situations where conventional computer vision based systems fail.

Pixel-level accuracy

Hyperspectral imaging involves capturing data on light reflected off an object using multiple wavelengths across the electromagnetic spectrum. This data is then analyzed by a machine learning algorithm pixel-by-pixel, to determine what type of materials the object is composed of. Unlike traditional computer vision techniques which infer the material type based on its shape, hyperspectral imaging scientifically determines the composition of the underlying material by determining how the different wavelengths of light are reflected back for every pixel.

Unique Benefits

Conventional (non-hyperspectral) vision-based sorting systems infer an object’s material type based on its shape. However, packaging is ever involving and often sourced from multiple suppliers, leading to a variety of objects whose material type cannot be determined by shape alone. The objects shown below, for instance, are visually nearly identical yet made from different materials.

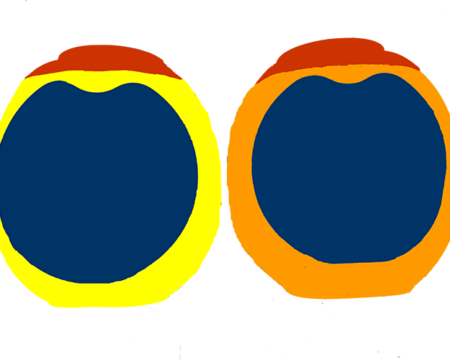

As seen below, the same container is made with either PET or HDPE. Furthermore, the caps are made from a different material altogether, PP, whereas the labels are made of paper. These subtleties would all be missed by conventional computer vision-based sorting systems, and would result in the introduction of significant contamination.

Another benefit of this pixel-level accuracy is that it allows for powerful IFTTT (If This Then That) rules when sorting objects mechanically in an industrial recycling facility. For example, a rule can be set up to remove an object from a PET stream if it is wrapped in a non-PET label for more than 80% of its surface area, since removing the label mechanically will likely fail, and shredding the object as is will end up contaminating the otherwise pure PET.

Finally, pixel-by-pixel level hyperspectral systems can identify the proverbial needle in a haystack. In the world of plastics recycling, PVC is a dangerous contaminant that spoils production if detected even at levels of 1 part per million. Dubbed the Poison Plasticby Greenpeace, the disposal of PVC results in the release of toxic, chlorine-based chemicals. Hyperspectral systems can detect such rare yet hazardous substances and identify them for removal with high accuracy before they result in non-reversible contamination.

Conclusion

Hyperspectral imaging offers an unprecedented level of accuracy and efficiency for industrial recycling plants. By providing pixel-by-pixel level identification of materials, it succeeds where conventional computer vision based systems fail. Its ability to detect contaminants, like PVC, ensures that no harmful material enters the production chain during processing, while its ability to scientifically identify plastic packaging increases purity rates for recycled material streams — leading to higher quality products downstream and higher profits for recyclers.